25 years of sensor technology – X-Sensors celebrates its anniversary

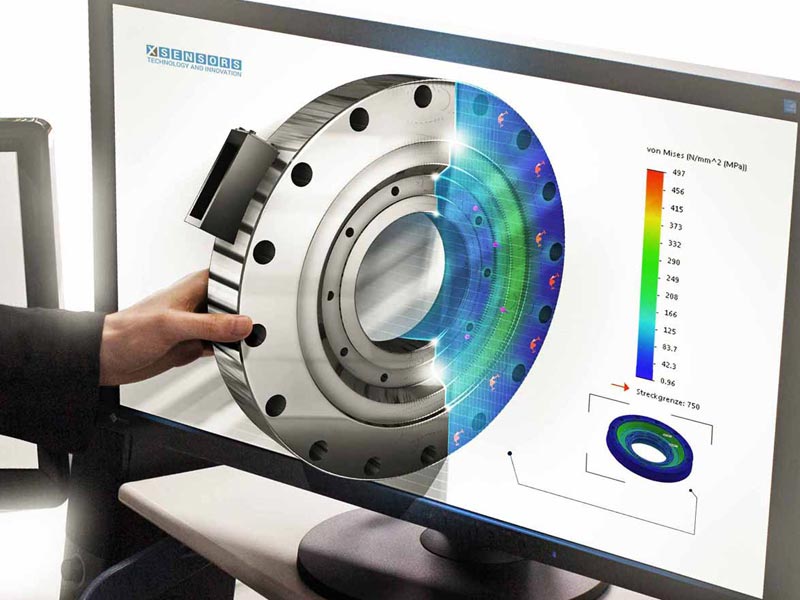

X-SENSORS – Stain Gauge Sensors and Accessories

At X-Sensors, everything revolves around high-precision strain gauge sensors for force and strain measurement – including suitable accessories. Whether customised OEM solutions or proven standard sensors from series production: everything remains in our hands – from development and production to final testing. Our sensors are used worldwide in industry, e.g. in injection moulding machines, presses and automated guided vehicles, as well as in passenger transport applications such as lifts and cable cars.

You can rely on Swiss precision, quality and durability – combined with a fair price-performance ratio. Because with us, reliability is not just a claim, but a Swiss tradition.