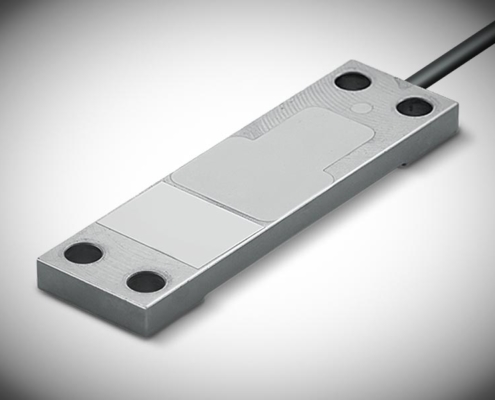

Measurement of the nozzle pressure

The measurement of the nozzle pressure is very linear and zero-point stable. The sensors are FEM-optimised and robust up to 150 percent. They have outputs and can be precisely adjusted to the required injection force. The sensors are very temperature-stable and maximise the consistency of the shot weight.

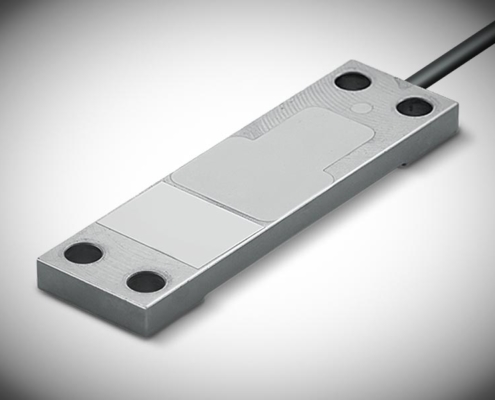

Injection pressure behind the Screw Feeder

The measurement of the injection pressure behind the screw conveyor is very linear and zero-point stable. The sensors are FEM-optimized and robust up to 150 percent. They have outputs and can be precisely adapted to the required injection force. The sensors are very temperature stable and allow maximum consistency of the shot weight.

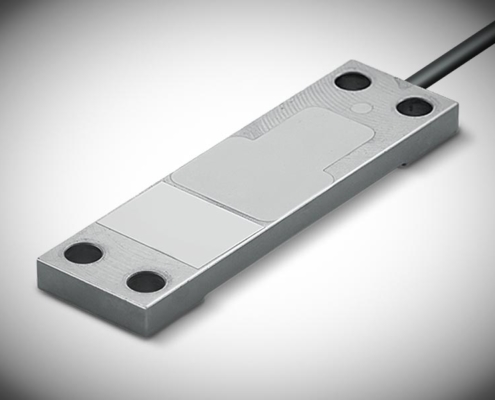

Clamp force and mold protection measurement

A functioning mold protection protects tools and machines. At the same time, a very sensitive Force measurement can be achieved with appropriate Sensors.

A measuring amplifier provides resolution down to the kilogram range, so that even PET bottle caps are not destroyed. By using two sensors that measure the force flow in the lower and upper flaps, collisions are detected over the entire mold area.