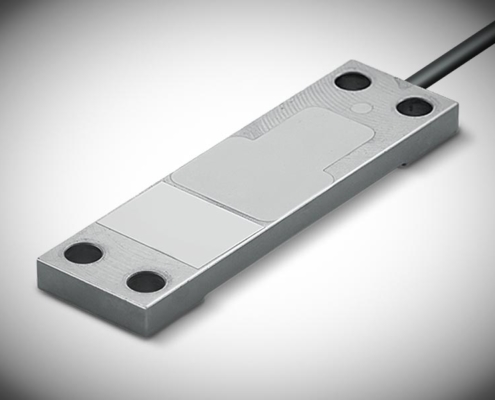

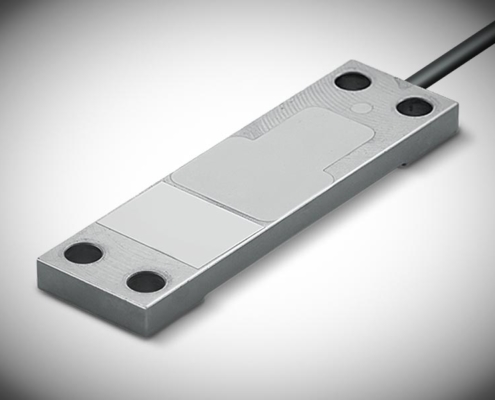

Measurement at the fixing point

Sensors for measurement at the fixed point can be easily mounted.

Only short cables need to be laid from the measuring point to the control system. This method has no influence on the legally required overhead clearance of elevators and is therefore particularly suitable for modernization projects. The sensors have an innovative and effective overload protection.

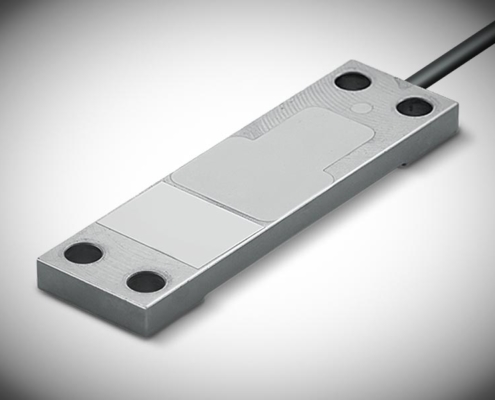

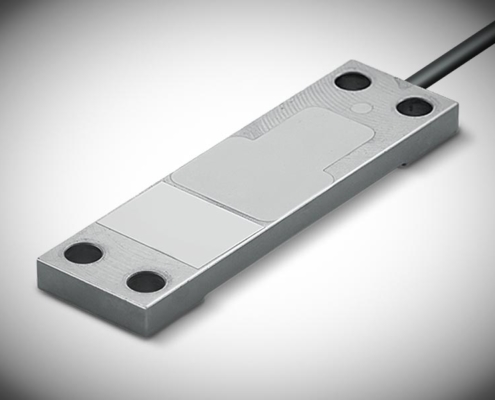

Measurement at the yoke

Measurement on the yoke is a cost-effective solution because only one sensor is required, which can be easily mounted without mechanical modifications. At the same time, the accuracy can be significantly increased by connecting a second sensor to the evaluation unit. The sensors are overload-proof, the method is suitable for modernizations and for new installations.

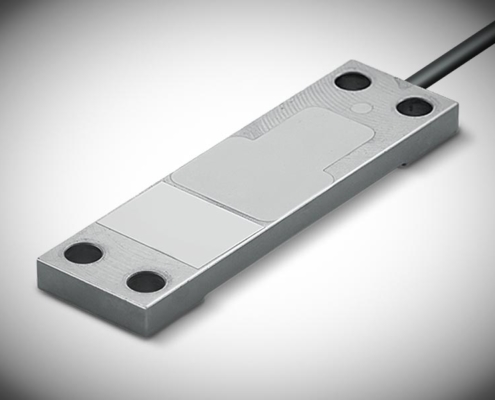

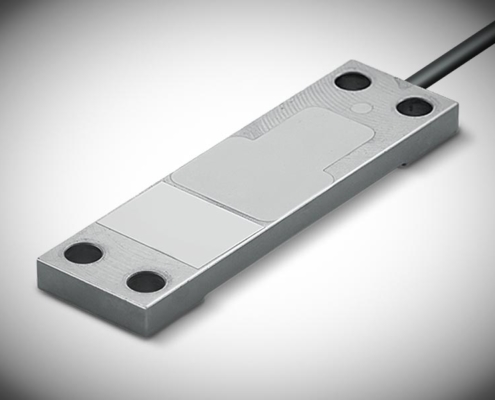

Measurement on the cabin floor

Measurement at the cabin floor enables maximum measurement accuracy. Zero load measurements are accurate to within 5 kg, so that empty cabins can be detected with

empty cabins with certainty. Due to the high resolution of the sensors (1:1000), small loads (up to 5 kg) can be measured as accurately as large loads (up to 10 t).

(up to 10 t) can be measured accurately.

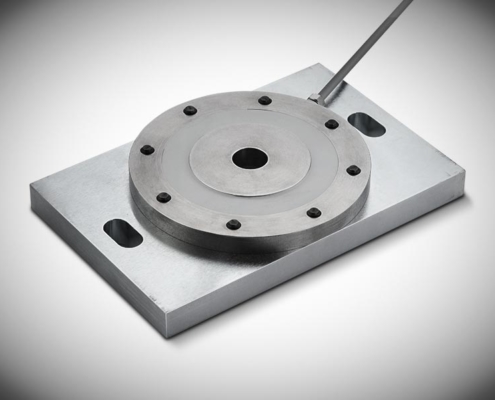

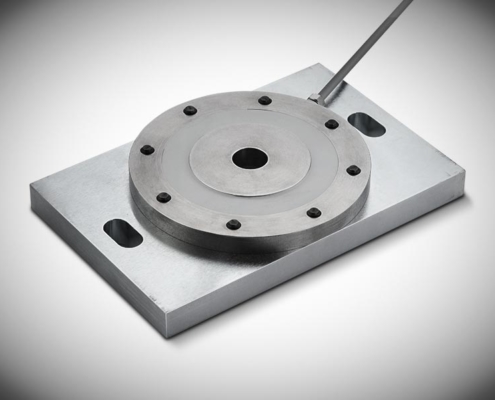

Measurement at the frame

Strain sensors measure the bending up or the strain of the press frame. This deforms proportionally to the acting force. In this way, the press forces can be measured very easily and overload-proof. This method is cost-effective and does not require any height in the press working area. Due to the spatial distance to the process, the sensors are well protected and easy to install.

Load measurement system / Elevation system

Evaluation units convert the measured values from sensors into current, voltage, frequency, LONbus, CAN bus, CANopen, relay output, etc....

The electronics carries out a zero point correction through the floor detection for particularly precise measurement results. Furthermore, the evaluation units have a programmable slack rope detection.